Service: +49 (0) 7644 - 91412 - 0 | Send a mail

Studies have shown that merely making references to monitoring systems brings about a reduction in transport damage!

It is often required that a sensitive packaged good must not be tilted out of a defined plane during transport. The tilt indicator is a simple aid that determines whether improper handling has taken place contrary to the transport instructions.

The tilt indicator is made of red plastic. The back is self-adhesive for attachment to the packaging. Small blue glass balls are contained in a bifurcated chamber, with two arms pointing downwards to the left and right and topped by an arrow. The blue balls are kept back below a metal band, so that the arrow at the top is white. When this retaining mechanism is removed, the blue balls are free to move into the arrowhead when the package and the tilt indicator are tilted. The triangular arrowhead above the bifurcation has an adhesive floor, to which the balls adhere when the tilt indicator is turned left, right, backwards, forwards or on its head. The indicator is irreversible and thus provides reliable monitoring. The tilt indicator can be attached on the inside or outside of the packaging or to the packaged good itself.

We recommend attaching two tilt indicators to the packaging to increase security. The tilt indicators should be labelled in order to prevent any tampering. It is also important to tell the freight forwarder and the recipient about the tilt indicator(s). Dimensions: 75 x 95 mm².

Shockmaster® indicators are used to show impacts suffered by packaged goods.

The device is used to find out or provide proof of whether a packaged good has been stressed more than permissible during transport and storage, or has suffered damage that can only be determined when the packed good is closely inspected.

The Shockmaster® consists of a spring-loaded weight with an integral trigger, which engages with a spring-loaded sleeve, the entire assembly being enclosed in a conical metal housing with a transparent dome. When a shock occurs, the weight is forced down against its spring. If the shock is of sufficient magnitude, the trigger is disengaged from the sleeve, which in turn is forced by its own spring to move along a rod, exposing a red warning band.

After tripping, the Shockmaster® can be reset again by removing the screw from the threaded hole in the side of the dome, inserting a stiff wire or straightened paperclip in the hole, and pushing the black sleeve back to its cocked position above the red marking.

For Shockmasters® with ratings of 25 Gs or more, the plunger in the dome is depressed while the sleeve is pushed back as far as possible. The plunger is then released and the sleeve is allowed to return gently to its cocked position. The two holes in the dome can be closed using sealing screws so that it is impossible for unauthorised persons to reset it and neither dust nor moisture can penetrate, The housing is made of anodised aluminium.

Shockmasters® may be mounted on the inside of the container or on the packaged item, depending on the information desired. There are four mounting holes in the base for rear mounting, or a mounting plate is available for front mounting of the units. The individual Shockmasters® react to impact stresses from all directions.

Impacts that take place vertically on the transparent top part, i.e. parallel to the longitudinal axis or at an angle of 45° have no effect. The attachment of two Shockmasters® is sufficient to be able to indicate impacts from all directions. Shockmasters® are available from stock in nominal ratings of 5, 10, 20, 25, 30, 35, 40 and 50 Gs. Other settings are available upon request.

The goods packed in cartons and crates are inevitably exposed to certain stresses in the form of collisions and even heavy impacts during transport. In order to monitor and document the forces affecting a consignment we offer the DROP-N-TELL® impact indicator with 6 different G values and in two versions.

The device is available with G values of 5, 10, 15, 25, 50 and 100 G and in two versions:

The red DROP-N-TELL® is equipped with two indicator arrows. If the package receives a collision or heavy impact larger than the G value defined on the DROP-N-TELL® device, the impact indicators are triggered and the indicator arrow changes from red to BLUE. Two units with the same G value should always be attached to the package because the DROP-N-TELL® can only show one collision or impact direction. One DROP-N-TELL® for vertical impacts and one for horizontal ones. It is necessary to consider on a case-to-case basis whether a third impact indicator is necessary in order to monitor and document all three axes.

The back of the DROP-N-TELL® impact indicator is self-adhesive. If the impact indicators are attached to wooden cases they should also be mounted with two small wood screws.

A two-part label is supplied with every DROP-N-TELL® impact indicator. The large label is attached to the package as a warning label. The smaller label is the reference label on the accompanying transport documentation. If the package is passed on to another freight forwarder he or she can instantly see that the package is provided with impact indicators. The freight forwarder should check the DROP-N-TELL® impact indicators to ensure that he or she has taken over the consignment in good condition.

| Packaged weight in kg | up to 0,03 | 0,03-0,14 | 0,14-0,43 | 0,43-1,42 | over 1,42 |

| 0 - 5,5kg | 100g | 100g | 50g | 50g | 25g |

| 0 - 12,5kg | 100g | 50g | 50g | 25g | 25g |

| 12,5 - 25kg | 50g | 25g | 25g | 25g | 25g |

| 25 - 45kg | 50g | 25g | 25g | 15g | 15g |

| 45 - 115kg | 25g | 25g | 15g | 15g | 15g |

| 115kg - 450kg | 15g | 10g | 10g | 10g | 10g |

| over 450kg | 5g | 5g | 10g | 10g | 10g |

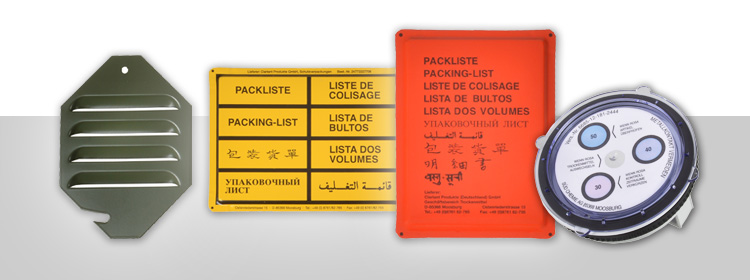

Packing list envelopes are designed to accept freight and transport papers, invoices or operating instructions. They protect against dirt, dust and moisture and have a self-adhesive back for attachment to packages.

Packing list envelopes are available with and without print for the formats DIN A4, DIN A5 and DIN A6 and made of Kraft paper or LD polyethylene. Our packing list envelopes made of environmentally friendly LD polyethylene are recyclable and do not affect groundwater. No poisonous gases are released on burning.

We also offer packing list covers made of aluminium sheet for export and for packaging units made of wood. They protect against dirt, dust and moisture and are reusable. We offer the following formats from stock: DIN A4, DIN A5 and DIN A6.