Service: +49 (0) 7644 - 91412 - 0 | Send a mail

Container Dri®II is an effective and inexpensive dehumidifying agent consisting of granulated calcium chloride (CaCl2) and starch. At the correct dosing, Container Dri®II reduces the relative humidity of air and thus the risk of condensation forming.

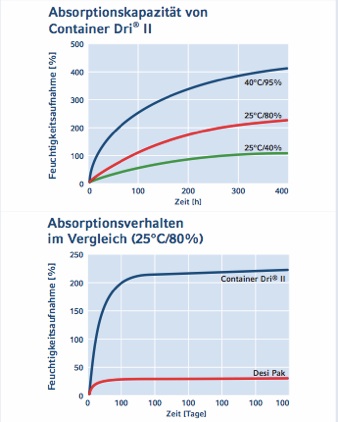

The extremely high absorption capacity at high air humidity (>200% capacity at 25°C and 80% RH) is a major advantage of Container Dri®II over conventional desiccants. This means that the moisture in a large volume of air can be reduced with a relatively low number of bags. As a result of its high capacity, it is often possible to do without the otherwise necessary additional anti-humidity barrier.

Conventional desiccants such as bentonite (DESI PAK®), silica gel (Sorb-It) and molecular sieves (Tri-Sorb) have a capacity of about 20% even at very low air humidities (< 40% RH). The capacity only increases slightly with increasing humidity. On the other hand, these desiccants achieve a very low residual dampness – which can lie below 5% RH – after adsorption has taken place. So these desiccants are used when:

In contrast, Container Dri®II has a very high capacity with high levels of humidity (> 40% RH), that increases strongly with rising air humidity. Container Dri®II , however, only achieves a residual air humidity of about 50%.

Container Dri®II is therefore properly used:

In principle, conventional desiccants can also be used for these purposes – but due to their low capacity, however, a very high quantity would be required. In addition, most of the capacity would be used to reduce dampness to a level that is by no means necessary for the application.

Top: The range of application of Container DRI®II

Bottom: Divergence from conventional desiccants (e.g. DESI PAK®)

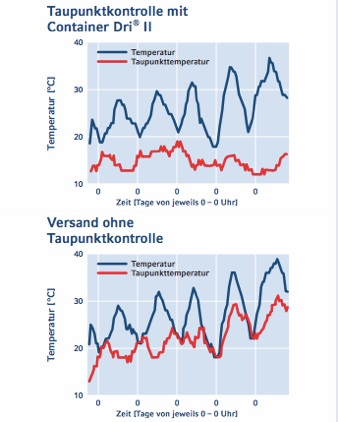

Top: Dew point control and prevention of condensation using Container DRI®II

Bottom: Transport without dew point control or active prevention of condensation in the container

| Part No. | Description | Packaging |

|---|---|---|

| B012105 | 125g standard bag | 90/carton |

| 200004007 | 125g bag with adhesive backing | 90/carton |

| 2000013409 | CD II Plus 3x4 = 12 connected pouches in hang-up bag | 6/carton |